Home

>

Products > Machining Center

> CNC Vertical Machining Center

>

CNC Vertical Machining Center 850

Products

CNC Vertical Machining Center 850

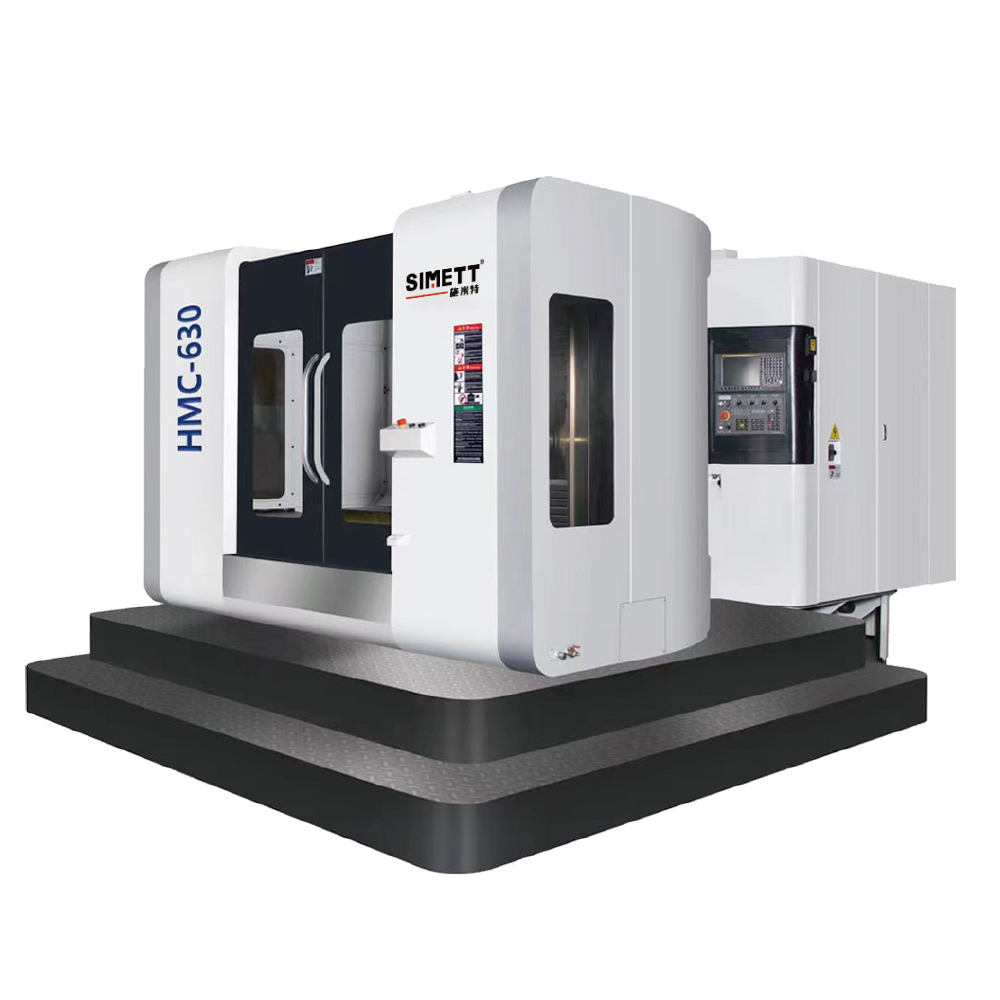

SIMETT, a respected manufacturer in the CNC Vertical Machining Center 850 sector, is renowned for its high quality CNC Vertical Machining Centres designed to deliver exceptional performance and reliability. With a strong focus on precision and durability, SIMETT has established itself as the supplier of choice for companies seeking cost-effective solutions without compromising on quality.

Model:SMTVMC-850

Send Inquiry

Product Description

The company's commitment to excellence is reflected in the design and manufacture of its CNC Vertical Machining Center 850, which are built to the highest standards to ensure consistent and reliable operation.The SIMETT CNC Vertical Machining Center SMTVMC-850 is a model that showcases the company's dedication to precision, performance, and value.

Standard Spindle Taper: The CNC Vertical Machining Center 850 is equipped with a BT40 spindle taper, a universal standard that ensures compatibility with a wide range of high-precision tooling.

High Spindle Speed: The main spindle of the CNC Vertical Machining Center 850 operates at speeds up to 10,000 RPM, suitable for high-speed machining operations and allowing for the efficient completion of intricate work.

Powerful Main Spindle: Available in two power options, 7.5KW or 11KW, the main spindle provides the flexibility to handle various machining tasks with ease.

Generous Axis Travel: The CNC Vertical Machining Center 850 offers an X-axis travel of 800mm, and equal Y and Z-axis travels of 500mm, providing ample space for large and complex workpieces.

High Rigidity Construction: The CNC Vertical Machining Center 850 is built with a high-rigidity frame that ensures minimal vibration and deflection, contributing to superior machining accuracy.

Advanced CNC Technology: The integration of advanced CNC technology allows for automated and complex machining operations with high precision and repeatability.

Versatile Applications: The CNC Vertical Machining Center 850's advanced features make it suitable for a wide range of applications, from simple to complex parts, across various industries.

Efficient Operation: The CNC Vertical Machining Center 850 is designed to maximize productivity, with features that minimize downtime and enhance the efficiency of the machining process.

User-Friendly Interface: The control system is intuitive and easy to operate, allowing operators to program and manage the machining process with ease.

Comprehensive Warranty: A reliable warranty on core components, along with strong after-sales service, demonstrates SIMETT's confidence in the machine's quality and performance.

While SIMETT does not offer customization services, the CNC Vertical Machining Center 850comes with a standard set of features that make it a versatile and reliable choice for a wide range of machining needs.As SIMETT moves forward, the company is committed to maintaining its reputation for delivering high-quality, reliable, and cost-effective products. It aims to continue providing machines that are robust, efficient, and technologically advanced, without the need for customization. SIMETT's vision is to be the trusted partner for businesses seeking premium standard machinery that offers excellent performance and value. With a customer-centric approach, SIMETT is dedicated to building lasting relationships and contributing to the success and growth of its clients, ensuring that every machine it produces represents a combination of high rigidity, high speed, and high precision.

| Product Specifications | |

| Machine Name: | CNC Vertical Machining Center |

| Machine Model: | SMTVMC-850 |

| Travel: | |

| *-A*is Travel (mm): | 800 |

| Y-A*is Travel (mm): | 500 |

| Z-A*is Travel (mm): | 500 |

| The distance from bottom of spindle to table top (mm): | 120~620 |

| Table Top: | |

| The area of table top (mm): | 1000*500 |

| The Ma*. Loading Weight (kgf): | 500 |

| T-Shape Groove (W*NO.*p) (mm): | 18*5*90 |

| Spindle: | |

| Spindle Taper: | BT40 |

| Spindle Speed (rpm): | 10000 |

| The diameter of spindle bush (mm): | Φ150 |

| The power of spindle (kW): | 7.5/ 11 |

| The driving type of spindle: | Belt-driven |

| The couterweight of Z-A*is: | NO |

| Feed Speed: | |

| The speed of */Y/Z-A*is (m/min): | 48/48/48 |

| The speed of cutting feed (mm/min): | 1-10000 |

| Min. input unit (mm): | 0.001 |

| The power of servomotor of */Y/Z-A*is (kW): | 2/2/3 |

| The width of */Y/Z-A*is guideway (mm): | 34/34/34 |

| The type of */Y-A*is guideway: | Roller Guideway |

| The type of Z-A*is guideway: | Roller Guideway |

| Automatic Blade Changing: | |

| Cutting Tools Number (pcs): | 24 |

| Shank bolt: | P-40T(45°) |

| Ma*. cutting tool weight (kg): | 8 |

| Ma*. cutting tool length (mm): | 300 |

| Ma*. cutting tool diameter (mm): | Φ80 |

| Ma*. diameter between two cutting tools (mm): | Φ120 |

| The Time of tool changing (T to T) (sec): | 1.8 |

| The type of tool changing: | Twin Arm with Gripper |

| Precision: | |

| Positioning Precision (mm): | 0.012 |

| Repeat-Positioning Precision (mm): | 0.008 |

| Others: | |

| Site Area (length*width) (mm): | 2600*2600 |

| Ma*. height of machine (mm): | 2800 |

| Machine weight (kg): | 5000 |

| Air Pressure (bar): | 6~8 |

| Electricity capacity (kVA): | 20 |

| CNC system: | FANUC-0iMF/MITSUBISHI-M80 |

|

|

|

| Accessories: "√" means the standard accessories; "*" means the NOT AVAILABLE accessories; "O" means the optional accessories | |

| Standard Accessories: | |

| The hear e*changer of electrical bo* | √ |

| Pre-pulled screw of Triple-a*is | √ |

| Unclamping unit | √ |

| Automatic Oil Feeding Lubricatinig Device | √ |

| All cover chip-free metal plate Cover | √ |

| Dust-free device of electrical bo* | √ |

| chip-free device with air curtain of the bottom of spindle | √ |

| Machine interior light | √ |

| Tricolor warning light | √ |

| rigidty tapping | √ |

| Foundation screw and block | √ |

| operating and maintenance manual | √ |

| Tool kit | √ |

| Types of spindle |

|

| belt-driven type 6000rpm | * |

| belt-driven type 8000rpm | O |

| belt-driven type 10000rpm | √ |

| belt-driven type 12000rpm | O |

| integrated motor type 12000rpm | O |

| integrated motor type 15000rpm | O |

| two-stage gear bo* 6000rpm | * |

| Oil cooler of spindle | O |

| CTS system | O |

| Control System |

|

| FANUC-0iMF | √ |

| SIEMENS-828D | O |

| MITSUBISHI-M80 | O |

| KND | O |

| Cooling system |

|

| Cutting fluid cooling system | O |

| Spindle cooling ring | √ |

| workpiece blowing | √ |

| Chip conveying system |

|

| base chip-flushing function | √ |

| Top cover shower function | O |

| flushing water gun/ air gun | √ |

| chip conveying machine | O |

| Oil-water separation system |

|

| specific gravity type Oil-water separation device | √ |

| Circle pad type Oil-water separation device | O |

| Lubricating system |

|

| Automatic Oil Feeding Lubricatinig Device | √ |

| Automatic Grease Feeding Lubricatinig Device | O |

| ATC |

|

| BT40 Shank specification | √ |

| BT50 Shank specification | * |

| HSK Shank specification | O |

| 24T disc type tool magazine | √ |

| 30T disc type tool magazine | O |

| Error compensation system |

|

| */Y-A*is grating ruler | O |

| */Y/Z-A*is grating ruler | O |

| Electrical system accessories |

|

| Safety Door Security Device | O |

| Safety Door Security Device (CE) | O |

| Automatic contact breaking system | √ |

| The heat e*changer of electrical bo* | √ |

| The cooling air motor of electrical bo* | O |

| Cutting tool/ workpiece detective system |

|

| Automatic cutting tool length detector | O |

| Tool failure detector | O |

| Workpiece detector | O |

| Other Optional Accessories |

|

| No. 4 (4/5) A*is | O |

| Column overlength | O |

| Automatic safety door | O |

| Protective metal plate | √ |

Standard Spindle Taper: The CNC Vertical Machining Center 850 is equipped with a BT40 spindle taper, a universal standard that ensures compatibility with a wide range of high-precision tooling.

High Spindle Speed: The main spindle of the CNC Vertical Machining Center 850 operates at speeds up to 10,000 RPM, suitable for high-speed machining operations and allowing for the efficient completion of intricate work.

Powerful Main Spindle: Available in two power options, 7.5KW or 11KW, the main spindle provides the flexibility to handle various machining tasks with ease.

Generous Axis Travel: The CNC Vertical Machining Center 850 offers an X-axis travel of 800mm, and equal Y and Z-axis travels of 500mm, providing ample space for large and complex workpieces.

High Rigidity Construction: The CNC Vertical Machining Center 850 is built with a high-rigidity frame that ensures minimal vibration and deflection, contributing to superior machining accuracy.

Advanced CNC Technology: The integration of advanced CNC technology allows for automated and complex machining operations with high precision and repeatability.

Versatile Applications: The CNC Vertical Machining Center 850's advanced features make it suitable for a wide range of applications, from simple to complex parts, across various industries.

Efficient Operation: The CNC Vertical Machining Center 850 is designed to maximize productivity, with features that minimize downtime and enhance the efficiency of the machining process.

User-Friendly Interface: The control system is intuitive and easy to operate, allowing operators to program and manage the machining process with ease.

Comprehensive Warranty: A reliable warranty on core components, along with strong after-sales service, demonstrates SIMETT's confidence in the machine's quality and performance.

While SIMETT does not offer customization services, the CNC Vertical Machining Center 850comes with a standard set of features that make it a versatile and reliable choice for a wide range of machining needs.As SIMETT moves forward, the company is committed to maintaining its reputation for delivering high-quality, reliable, and cost-effective products. It aims to continue providing machines that are robust, efficient, and technologically advanced, without the need for customization. SIMETT's vision is to be the trusted partner for businesses seeking premium standard machinery that offers excellent performance and value. With a customer-centric approach, SIMETT is dedicated to building lasting relationships and contributing to the success and growth of its clients, ensuring that every machine it produces represents a combination of high rigidity, high speed, and high precision.

Hot Tags: CNC Vertical Machining Center 850, Manufacturer, Supplier, Factory, China, Wholesale, Buy, Customized, Made in China

Product Tag

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy